|

Home | Products | Support | Purchase | Contact |

NEC

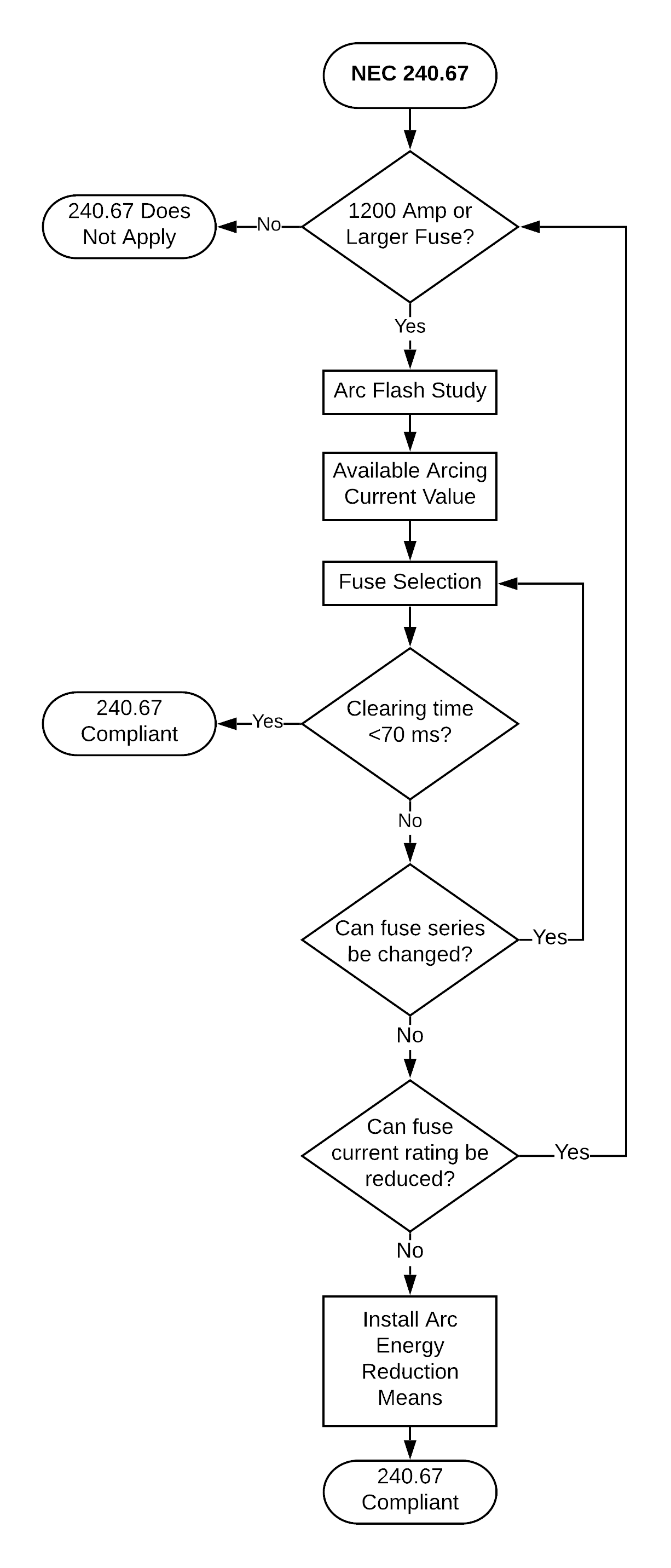

240.67 COMPLIANCE & NFPA 70E ELECTRICAL SAFETY

The points below offer guidance for NEC

compliance and electrical safety. Each point has

individual merit.

Point 1:

Fuses have different characteristics.

Not all

Class L fuses are the same. Fuse manufacturers offer

different fuse types, each with unique characteristics

and clearing times. Once you have calculated the

available arcing current, look at the clearing times

of all available fuses. In many cases, simply

installing the appropriate Class L fuse will reduce

arc energy to a compliant level and improve safety.

Some of the more popular versions and their

accompanying data sheets are listed below.

Bussmann:

KLU KRP-C

601-2000 KRP-C

2001-6000

Point 2: Size the fuses according to the

continuous load, not the switch size.

In most

cases, fusible switches are sized at least 25% larger

than the continuous load calculations. Install fuses

that are rated for carrying the continuous load

current, not based on the size of the switch. Smaller

fuses will react faster when an adverse condition

occurs. Class L fuses can be used at 100% of their

rating and are uniquely designed so downsizing

can almost always be done without special adaptors. It

can be argued that when fuses are rated less than the

current rating of the switch, an “energy-reducing

active arc flash mitigation system” is created.

Point 3: Install an Arc Energy Mitigation System.

If after

searching for an appropriate fuse it is determined

that none are available that reduce the clearing time

to the .07 second requirement, installing an

appropriate arc energy mitigation system should be

pursued. Arc flash detection relays and sensors are

readily available from several manufacturers. Install

the components in the sections or cabinets that the

fuses feed. Wire the trip signal of the arc flash

detection components to the shunt trip mechanism where

the fuses are mounted.

Point 4: Always avoid work near energized

conductors!

This cannot

be stressed enough. Always put energized conductors

into an electrically safe work condition by turning

off the switch. Apply lockout/tagout and approach the

conductors as if they are energized. The safest way to

work near conductors is when they are de-energized.

Even in cases where a maintenance mode is an option,

turning the switch OFF provides a safer environment

than an activated maintenance mode with the switch ON.

The links below can offer guidance on selecting the

proper method for your application.

Bussmann

Arc Reduction Calculator

Littelfuse NEC 240.67 Arc-Energy Reduction (Technical Paper)